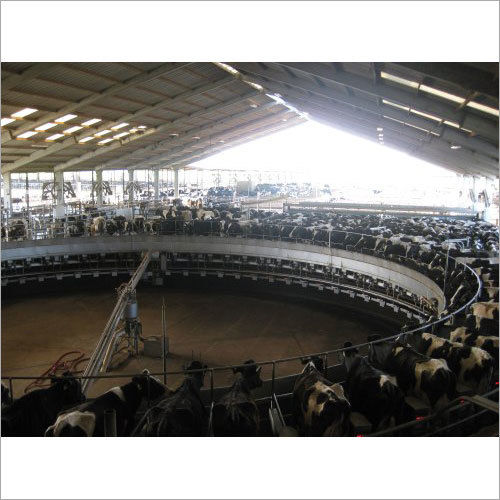

Rotary milking Parlor

Product Details:

- Product Type Rotary milking Parlor

- General Use Industrial

- Material Stainless Steel

- Type Automatic Rotary

- Capacity 16-80 cows per rotation (customizable)

- Weight (kg) Up to 3500 kg (varies as per capacity)

- Computerized Yes

- Click to view more

Rotary milking Parlor Price And Quantity

- 5-10 Unit

- 40000.00 - 50000.00 INR/Unit

Rotary milking Parlor Product Specifications

- Yes

- Rotary milking Parlor

- 16-80 cows per rotation (customizable)

- Automatic CIP (Clean-In-Place)

- Silver

- Integrated Milk Cooling Tank (optional)

- Automatic Rotary

- 380 V / 50 Hz

- Hot Water/Steam

- Good Quality

- Yes

- Industrial

- Stainless Steel

- 2.2-5.5 kW (varies per model)

- Up to 3500 kg (varies as per capacity)

- Programmable Logic Controller (PLC)

- Depends on capacity, e.g., 12m x 3m

Rotary milking Parlor Trade Information

- 1 Unit Per Week

- 1 Week

Product Description

Rotary Parlors we offer function as the carousel drives for dairy cows. They are needed to for farms for the milking the cow efficiently. They rotate counterclockwise. These have a large circular platform which interchange like a carousel and the cows are being milked. Rotary parlors have the entrance point as well, which enable them to work more efficiently. Productivity and functional efficiency are the main defining factors needed for a profitable operation. Also, they are offered with an uncompromised durability.

Product details

Minimum Order Quantity | 1 Unit |

No of Herds | 600 Milking Cow |

Capacity | 40 to 80 cows. |

Machine Body Material | SS |

Voltage | 380V - 420V |

Power | 7600 W |

Technique | Automatic |

Brand | Vansun |

Superior Milking Performance

Optimized for efficiency, the Rotary Milking Parlor enables rapid cycling, handling between 16 and 80 cows per rotation and milking up to 200 cows per hour. The robust design, featuring a programmable logic controller (PLC) and touch-screen interface, ensures smooth and precise operation, streamlining your dairy farms daily routine.

Advanced Animal Welfare and Safety

The system prioritizes cow comfort and handler safety with silicone rubber liners, low-noise operation, and hydraulic or pneumatic automated entry and exit. High-grade materials offer exceptional corrosion resistance, while safety mechanisms like emergency stop and overload protection keep operations secure and reliable.

Intelligent Data Management

With integrated RFID and computerized control, the parlor collects real-time milk yield and animal health data. This automated system seamlessly integrates with herd management, promoting informed decision-making and optimizing herd productivity.

FAQs of Rotary milking Parlor:

Q: How does the rotary milking parlor maximize milking speed and efficiency?

A: The rotary milking parlor is engineered with automatic operation and quick-entry hydraulic or pneumatic automation. Its circular design allows continuous movement, enabling up to 200 cows per hour to be milked efficiently. This configuration minimizes waiting times and improves throughput without compromising animal comfort.Q: What are the main benefits of stainless steel and food-grade plastic milking cups?

A: Both stainless steel and food-grade plastic cups provide hygienic and durable milking. Stainless steel is robust and highly corrosion-resistant, while food-grade plastic is lightweight and easy to handle. Both are compatible with silicone rubber liners for gentle milking, ensuring high-quality milk production and animal welfare.Q: When should the parlors automatic CIP (Clean-In-Place) system be used?

A: The automatic CIP cleaning system should be used after each milking shift or as specified by hygiene protocols. It uses hot water or steam to clean and sterilize the system internally, ensuring all components remain sanitized and milk safety is maintained.Q: Where is this automatic rotary milking parlor commonly installed?

A: This parlor is ideal for industrial dairy farms throughout India and other large-scale operations requiring efficient, high-capacity milking. With customizable capacity, it adapts to various farm sizes and infrastructure layouts.Q: What is the process for accessing and maintaining key parlor components?

A: Maintenance is simplified via tool-free, quick-access part designs. Operators can perform routine inspections and necessary servicing swiftly, minimizing downtime. The use of durable materials and an integrated cleaning system further reduces maintenance demands.Q: How does the milking parlor improve herd management?

A: Advanced RFID and automatic identification technologies collect data on each animals milk yield and health. This data integrates directly with farm management software, helping farmers track productivity, detect health issues early, and make evidence-based management decisions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese